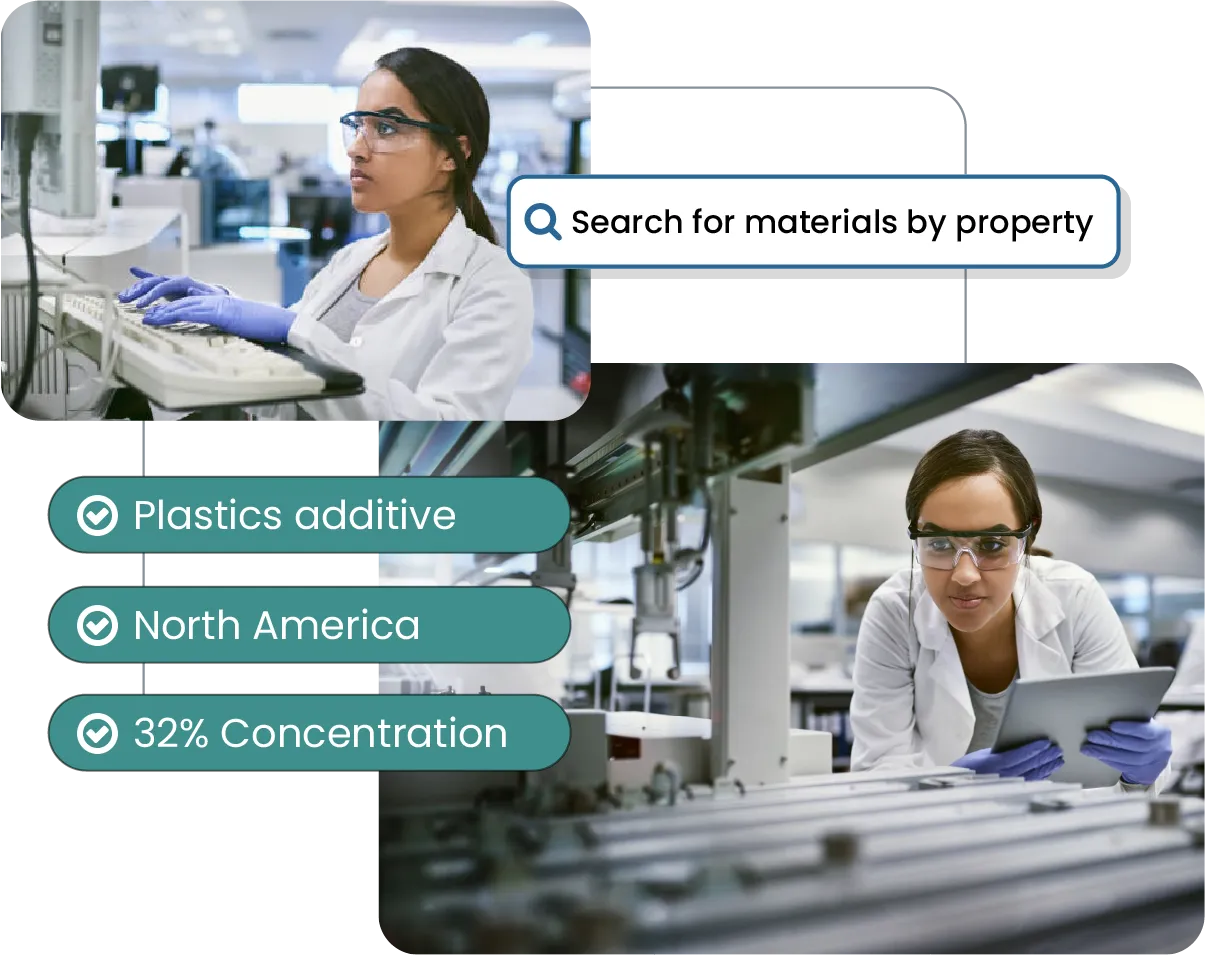

Source Your Materials

Find the materials you need to bring your product to market faster. Search thousands of materials from global suppliers by keyword, property, certification and more. Analyze technical data, request samples and contact suppliers with your free account.

Start searching nowMarket Your Materials

Promote your products to industry professionals engaged in material research. Learn more about UL's plastics and chemical marketing solutions to reach product developers, engineers, and chemical buyers.

Go To Marketing Solutions

Find the Materials You Need

The UL Prospector materials database helps you find plastics, chemicals and ingredients for your next formulation and product development challenge. Product formulators, engineers, and developers can locate technical data on hundreds of thousands of products in one easy-to-use search engine.

Create your free account to:

- Find materials, technical information and suppliers quickly and easily

- Search by material type, supplier, application, or functionality

- Stay informed with industry trends and information

Beyond materials search, Prospector also has starter formulations to accelerate your product development. You can request samples from multiple suppliers within your Prospector account for simple order organization. All product listings include the supplying company’s contact information for quick communication.

Access is free to qualified professionals. Simply complete the registration form to start finding materials.

Prospector offers additional services for select industries including:

-

Retailer and Regulatory Compliance Highlights

Analyze ingredient-level compliance information within Prospector for more than 200 global regulatory and advisory lists and 30 international retailer lists.

-

Enhanced search functionality

Utilize side-by-side comparisons, UL Yellow Card performance information, OEM/automotive approved materials, find alternative resins and more advanced search techniques.

-

Visual data representation

View curve multipoint data for performance characteristics, compare properties on a radar plot or explore material features plotted graphically.